7 reasons to work with a trusted HDPE Pipe Supplier

Wiki Article

Pipeline Manufacturer Spotlight: Discover the Best in the Industry for Your Next Job

In the domain name of pipeline manufacturing, the selection of maker can considerably influence the end result of your task. With a selection of firms providing innovative products and innovative solutions, recognizing the vital requirements for option comes to be vital. Market leaders like Tenaris, Vallourec, and United State Steel are at the forefront of offering lasting and reliable choices. The question remains: what particular elements should assist your decision-making process, and exactly how do these makers separate themselves in an increasingly competitive market? Discovering these facets might expose understandings that might influence your next task's success.Industry Introduction

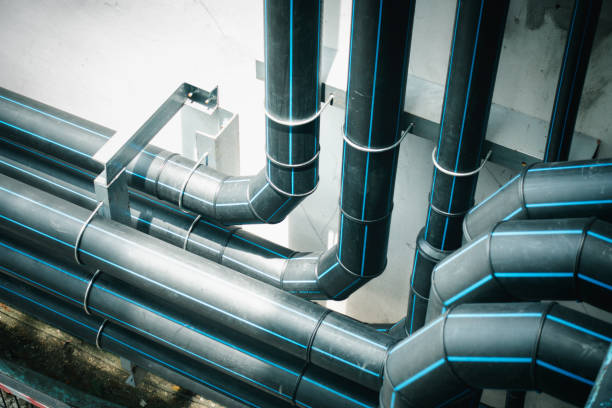

In the pipeline manufacturing industry, there exists a dynamic interplay of technical advancements and regulatory demands that forms market practices. This sector is essential for the transport of oil, gas, water, and other fluids, requiring a durable understanding of both material properties and ecological impacts. Manufacturers are progressively incorporating advanced materials and ingenious production techniques to enhance the resilience and efficiency of pipelines, ensuring they can withstand differing stress and environmental problems.

In enhancement, the surge of digital innovations has changed standard manufacturing processes, allowing for boosted surveillance and anticipating upkeep. This shift not just enhances functional effectiveness however likewise helps in reducing prospective failures before they intensify right into vital problems. In general, the landscape of pipeline manufacturing is identified by a continuous evolution driven by advancement and conformity, positioning the industry for future development and sustainability.

Key Requirements for Choice

Picking the best pipeline maker entails careful consideration of a number of crucial standards that assure dependability, efficiency, and conformity with sector standards. Examine the supplier's experience and credibility within the market. A reputable firm with a tried and tested record is more probable to supply top quality product or services.Next, evaluate the array of products and requirements supplied. Manufacturers must supply a range of choices that cater to diverse project needs, including various pipeline dimensions, materials, and covering systems. Conformity with appropriate market standards, such as ASTM or API, is important, as it ensures the products fulfill safety and security and efficiency criteria.

Additionally, think about the producer's technological capabilities. Advanced manufacturing strategies and top quality control actions can greatly impact the sturdiness and performance of the pipes. Customer support and support are additionally essential; a receptive and educated team can help with smoother project implementation and attend to any problems immediately.

Lastly, evaluate pricing frameworks and lead times. While cost-effectiveness is vital, it should not endanger quality. Stabilizing these criteria will certainly lead to an educated decision that straightens with project objectives and regulatory demands.

Top Pipeline Manufacturers

In the competitive landscape of pipeline manufacturing, numerous market leaders attract attention for their ingenious technologies and commitment to sustainability. These leading producers not only excel in delivering premium items but likewise focus on environmentally accountable techniques in their operations. A summary of their payments gives important understandings right into the future of pipeline solutions.Market Leaders Introduction

Just how do industry leaders shape the pipeline manufacturing landscape? The top pipeline makers play an essential role in establishing market standards, driving advancement, and assuring quality assurance throughout the supply chain. Companies such as Tenaris, Vallourec, and U.S. Steel have set criteria for security, efficiency, and sustainability, influencing not just their operations but likewise their competitors.These leaders invest considerably in r & d to improve item toughness and efficiency. Their dedication to sticking to regulatory compliance and worldwide standards cultivates customer trust and urges industry-wide fostering of best practices. They typically work together with stakeholders, including designers and building firms, to guarantee that their products fulfill details task demands and environmental considerations.

Market leaders likewise focus on client relationships, offering customized services and phenomenal service, which reinforces their market setting. By leveraging economic climates of scale, they can supply competitive prices without compromising quality. Eventually, the impact of these makers extends past their products; they form the future of pipeline modern technology and manufacturing processes, guaranteeing a lasting and resistant infrastructure for numerous industries worldwide.

Cutting-edge Technologies Provided

What cutting-edge technologies are transforming the pipeline manufacturing market? In recent times, top pipeline suppliers have accepted sophisticated technologies to improve performance, reliability, and security in their procedures. One substantial development is the combination of clever pipeline monitoring systems, making use of Net of Things (IoT) sensors. These systems give real-time data on pipeline conditions, allowing positive upkeep and reducing the risk of failures or leaks.

In addition, manufacturers are increasingly embracing innovative products, such as composite pipelines, which offer improved durability and resistance to rust. These materials not only prolong the life-span of pipes yet also decrease operational expenses gradually. In addition, additive manufacturing, or 3D printing, is transforming the production process. This innovation permits quick prototyping and modification of parts, simplifying supply chains and reducing waste.

Artificial intelligence (AI) and machine learning algorithms are additionally obtaining grip, maximizing style processes and predictive maintenance schedules. By analyzing huge datasets, these technologies help identify possible concerns prior to they emerge, boosting security and operational efficiency. As these innovative technologies remain to advance, they promise to shape the future of pipeline manufacturing, ensuring that tasks can be finished promptly and within budget while keeping miraculous safety criteria.

Sustainability Practices Highlighted

The recurring improvements in ingenious technologies within the pipeline manufacturing sector are enhanced by a growing emphasis on sustainability methods among top manufacturers. These firms are progressively adopting green approaches, minimizing waste, and reducing their carbon impacts throughout the manufacturing procedure.Leading producers are focusing on the use of recycled materials, improving the lifecycle of their items. By implementing closed-loop systems, they effectively use resources, therefore decreasing the ecological impact connected with raw product extraction and processing. In addition, several organizations are spending in renewable resource sources to power their procedures, further minimizing greenhouse gas emissions.

In addition, pipeline makers are welcoming advanced layers and materials that boost rust resistance and durability, which ultimately reduces the regularity of replacements and repairs. These sustainable methods not only add to ecological stewardship yet additionally align with the growing regulatory demands and market expectations for accountable manufacturing.

In addition, cooperation with stakeholders to cultivate sustainability initiatives showcases a commitment to a greener future. By concentrating on sustainable methods, leading pipeline makers are not just improving their functional effectiveness but also setting a benchmark for sector criteria, advertising an extra lasting pipeline framework for all.

Cutting-edge Technologies

The pipeline market is experiencing a transformative change with the combination of ingenious innovations, particularly in advanced products growth and wise pipeline tracking systems. These developments not only boost the toughness and effectiveness of pipelines but additionally improve safety and security and ecological stewardship. As makers embrace these cutting-edge remedies, the future of pipeline facilities looks progressively encouraging.Advanced Materials Development

Technologies in sophisticated products development are changing the pipeline manufacturing market, driving enhancements in performance, toughness, and efficiency. The appearance of high-strength alloys and composite products has made it possible for the manufacturing of pipes that can hold up against extreme problems, including high pressure and destructive environments. These materials not only extend the life-span of pipelines however additionally reduce maintenance prices, ultimately causing boosted operational effectiveness.

Additionally, innovations in polymer science have resulted in the development of light-weight, adaptable piping systems that are easier to install and carry. These developments contribute to reduce carbon footprints in pipeline jobs, lining up with worldwide sustainability goals. Furthermore, the assimilation of nanotechnology in product growth is opening up brand-new avenues for enhancing the mechanical residential or commercial properties of typical products, causing pipelines that can withstand higher tension while maintaining integrity.

As manufacturers remain to buy r & d, the pipeline industry is witnessing an unmatched evolution in product abilities. This focus on advanced products not just supports the expanding need for trustworthy facilities but additionally cultivates a competitive landscape wherein firms can distinguish themselves through premium item offerings. The future of pipeline manufacturing is certainly linked with these groundbreaking improvements.

Smart Pipeline Checking Solutions

Smart click this site pipeline monitoring systems are changing the landscape of pipeline management by incorporating advanced technologies such as IoT sensing units, synthetic knowledge, and real-time data analytics. HDPE Pipe Supplier. These systems allow drivers to keep an eye on the integrity and efficiency of pipes constantly, significantly reducing the danger of leaks and failuresVia the deployment of IoT sensing units along pipeline courses, operators collect important information on circulation, temperature level, and pressure rates. This information is sent in real-time to centralized tracking systems, permitting prompt assessment and action to abnormalities. Advanced expert system algorithms examine this information to recognize patterns, predict possible concerns, and recommend preventative actions before they rise into pricey troubles.

The execution of wise surveillance systems not just boosts functional performance but also promotes conformity with governing requirements. By giving detailed reports and insights, these technologies support better decision-making and danger administration. In addition, the integration of artificial intelligence capabilities allows systems to enhance gradually, adjusting to altering conditions and improving predictive accuracy.

As the industry remains to embrace these developments, smart pipeline monitoring systems are poised to play a pivotal function in ensuring the safety, reliability, and sustainability of pipeline framework. HDPE Pipe Supplier.

Study of Success

Success tales within the pipeline manufacturing industry brighten the efficiency of cutting-edge solutions and cooperation among stakeholders. One remarkable situation is the partnership between a leading supplier and an oil business to implement a modern clever pipeline surveillance system. The job considerably minimized leakage detection times and boosted functional performance, showcasing the value of innovative technology in boosting security and minimizing costs.One more instance involves a manufacturer that successfully incorporated lasting materials into their pipeline building. By teaming up with research establishments, they developed a composite material that is not just long lasting yet also eco-friendly. This development not just met regulative needs but additionally drew in brand-new customers looking for sustainable services.

A pipeline job in a tough geographical area showed the relevance of adaptive engineering techniques. The producer worked together with local designers to make a pipeline that might hold up against severe climate condition, eventually stopping solution disturbances and making certain integrity for end-users.

These instance researches exhibit just how critical collaborations, technical advancements, and adaptive solutions in the pipeline manufacturing sector lead to effective task end results, thus strengthening the market's commitment to delivering premium facilities while dealing with client needs effectively.

Sustainability Practices

As the pipeline manufacturing industry progresses, the integration of sustainability techniques has actually become progressively important. Manufacturers are embracing environment-friendly materials and processes to lessen their environmental effect while keeping high requirements of top quality and safety. This shift is driven by both governing requirements and a growing understanding of ecological responsibility amongst stakeholders.

One prominent method is using recycled materials in pipeline manufacturing, which reduces the demand for virgin resources and reduces waste. Business are additionally investing in energy-efficient manufacturing techniques, consequently lowering their carbon footprint during production. In addition, numerous producers have adopted water conservation methods, making certain that water use is minimized and wastewater is dealt with properly.

Furthermore, sustainable transport approaches are being used to supply products, consisting of enhancing logistics to decrease exhausts. The commitment to lifecycle assessments permits suppliers to examine the environmental impact of their items from creation to disposal, promoting not just sustainability however likewise long-term financial practicality.

Ultimately, the fostering of sustainability methods in pipeline manufacturing signifies an essential step towards aligning market operations with worldwide environmental goals, making sure that future jobs are both accountable and ingenious - American Plastics LLC HDPE Pipeline Manufacturer. - HDPE Pipe Supplier

Future Fads in Pipeline Manufacturing

What innovations are on the horizon for pipeline manufacturing? As the industry develops, several essential trends are shaping the future of pipeline production. First, the integration of advanced materials such as composite pipelines assures boosted durability and resistance to corrosion, thus extending the lifespan of pipelines. These materials not just minimize maintenance costs yet additionally enhance safety standards.

Sustainability stays a crucial focus, with suppliers increasingly prioritizing green practices. The advancement of eco-friendly products and the implementation of recycling programs are acquiring grip, straightening with international environmental goals.

Often Asked Concerns

What Products Are Generally Used in Pipeline Manufacturing?

Common materials utilized in pipeline manufacturing consist of carbon steel, stainless-steel, polyethylene, and ductile iron (Texas Pipeline Manufacturer). Each product offers distinct benefits pertaining to toughness, rust resistance, and viability for numerous applications within the pipeline industryHow Long Does the Pipeline Manufacturing Refine Commonly Take?

The pipeline manufacturing process generally ranges from a couple of weeks to a number of months, relying on variables such as product selection, production capacity, and personalization demands. Effective preparation and sychronisation can substantially affect the total timeline.What Are one of the most Common Pipeline Sizes Available?

One of the most common pipeline dimensions vary from 2 inches to 48 inches in size. Irregularity exists based upon certain applications, market requirements, and regional demands, guaranteeing versatility to meet diverse project demands and functional demands.Exist Guarantees Used on Pipeline Products?

Yes, numerous pipeline producers provide warranties on their items, commonly covering product flaws and craftsmanship. The duration and regards to these service warranties differ by producer, so it is vital to evaluate specific plans prior to purchase.Just how Do I Make Certain Appropriate Installation of Pipes?

To assure appropriate installation of pipes, comply with industry criteria, use qualified professionals, perform complete site analyses, carry out quality control measures, and safe and secure compliance with regulations. Normal assessments and maintenance additionally enhance pipeline efficiency and longevity.Pipeline suppliers are accepting advanced layers and materials that boost rust resistance and longevity, which eventually decreases the regularity of replacements and repair services. The pipeline industry is experiencing a transformative shift with the integration of ingenious modern technologies, especially in innovative materials advancement and clever pipeline monitoring systems. As suppliers continue to invest in study and advancement, the pipeline sector is seeing an extraordinary development in product capabilities. Smart pipeline tracking systems are transforming the landscape of pipeline administration by incorporating cutting-edge innovations such as IoT sensing units, artificial intelligence, and real-time information analytics. Yes, many pipeline makers supply warranties on their products, commonly covering product flaws and handiwork.

Report this wiki page